jos_br

New member

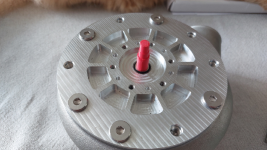

I mean charging with a 48v/100ah alternator and then converting to a 12v battery for the rest of the car. This one,I have looked into it.. There are two real SC kits i could buy for this car. One is a roots type and the other a rotex .. both dont bother with with a IC.. The higher the boost pressure the more you need a IC.. im talking here probably sub 6psi, which is less than the real SC kits. So i dont think it will do an awful lot... The other issue being is that there will be some drop across the IC and if thats say .5 psi then it takes a lot of electrical power to create that .5 psi and that increases charge time and reduces run time...

There are other draw backs too like it will all take more space and cost more to add one too... Also we need to remember that for 99% of the time the E-turbo will be off.

Ultimately i want something working i can always make it better later.

yeah i mean adding a second 48v alternator would be ideal if you can fit it in somewhere... For me trying to do that would be difficult and the simpler thing would be to upgrade the 12v one to start with....... At this point i just need to get something going and i can make these kind of plans after the fact.

Jos.