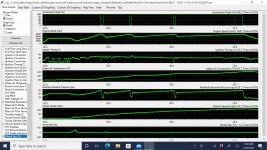

So if you're spinning 101,550 impeller rpm at 8,000 engine rpm, it means you should be around 93,000 impeller rpm at your hp peak - but the map shows about 5,000 impeller rpm less (more or less in the "meat" of my guess). I'd be very surprised if you you're not seeing belt slip - in my experience all blowers have some degree of slip, and it shows up as black dust in the engine bay (sometimes it's hard to spot if there's not much - and you're not seeing much.) If you're not running a charge cooler (I'm assuming you're not), your IATs are likely the result of sensor lag. They are much higher in reality. When you compress a gas, there's a calculatable rise in temp. Try this on-line calculator:

Site will be available soon. Thank you for your patience!

racingcalcs.com

Even with some slip, you're approaching the max rated rpm of the small blower anyway - something I hadn't take into account in the previous reply. Personally, that doesn't bother me as I haven't owned a supercharger I haven't overspun. My Eaton M90 had it the worst - rated to 11,000 rotor rpm, I was winging it close to 20,000 rpm at the shift.

Even with E85, you'd gain a lot from an intercooler - the charge would be denser, boost would go down, power would go up. Plus your tuning winodw would be larger. An A/W intercooler can't be beat, esp. for dragstrip use. The intercooler in a dragstrip environment functions more like a heat sink - there's not enough time to reach thermal equilibrium. Heck, try what we used to do back in the day on Fox body Mustangs (my LTD is a Fox body, too - I've done the same thing). Before a pass, put a bag of ice on the intake to get it as cold as possible. Then make a hit. Your IATs will go down and your car will be faster. Read the short paragraph after the list of stuff in the first post of this thread. Bob Cosby was legendary in the early years for getting those cars to run fast (for the time) with little to no mods:

The A/W intercooler in my car with the Whipple would melt 10-15 lbs of ice in a single pass! Listen to the audio in this video - before the pass you can hear a ton of ice knocking around inside the water tank (it was my center console/arm rest - so it's right under the camera); at the end of the pass you only hear a few pieces left. And that's a 3 gallon tank that I'd literally pack full of ice, with just enough water to circulate (I'd turn it on before the burnout):

BTW, that digital meter next to my soda that goes flying when the car launches is the water temperature in the A/W system. You can see it's at 38.7 degrees F just before launch.

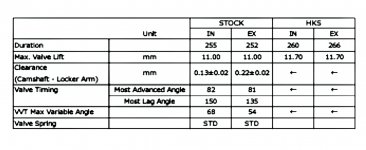

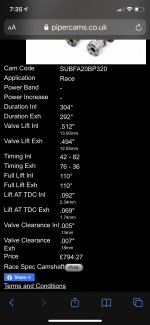

Keep in mind, I'm a V8 guy, so the next few points are from that perspective (the previous ones I feel are universal). I'm surprised you're not timing limited, even on E85, esp given your compression; DI and all not withstanding. For the cams, I'm afraid I'm not going to be much help. Your engine is a completely different beast than what I'm familiar with, and you're in an RPM range none of my V8s even came close to. And actually, one of the first things I notice is that there's no info given on weather the duration figures are advertised or at .050 lift (both pieces of data help us V8 guys know how "big" a cam will act and how aggressive the lobes are). I know several great cam guys in V8 world, but none the world you're in.

You have some choices to make - and much of it is outside my world of experience. You're already at what I consider higher boost, high RPM and high compression. I'm sure an A/W intercooler would help quite a bit. If you're sensible and not like me (I built my own A/W intercooler, even the core), you can check out

https://www.frozenboost.com/ - just go a bit oversized for your goals. It's always better to have a bigger motor, esp. when matched with better breathing. I do know that the bigger blower will cost you some low rpm torque, but that's not all that important in a drag strip scenario.

If you want maximum efficiency, and extreme ease of removal to keep the smog nazis at bay, well - you know what I'm going to suggest, right? An electric turbo powered by a TP Power motor and a Speedmaster P2. I'm putting together just that setup right now to play with it. Just today I ordered a VESC to control it (along with $3,000 worth of MGM controller/LMT motor for my Vortech setup).