Good question. There seems to be very little end float. I think it is mostly a combination of the nut loosening due to fast deceleration and flex in the back plate. I am still waiting on my laser sintered stainless shaft and hopefully they works for me. Here is the update. I will start a build page for my project as it is looking promising.

Well, my goal this weekend was to make some sort of boost in the basement And….At the last minute, goal achieved!

I was basically struggling to overcome the instability of 3D printed parts flexing under load and the compressor nut loosening causing interference between the compressor and volute housing.I greatly increased the rigidity of the backplate by probably 5-10X. I started using a cubic infill (vs zig zag) at 70% (up from 20% infill) and slowed down my printer to 70 mm/sec to get better layer to layer adhesion with my ABS filament. Once the design stops changing, I will eventually make an aluminum back plate. Problem solved.

Then I got out the dial caliper and made some adjustments to get the extension shaft run out below about 5 thousandths of an inch. This is the best I can do with the coupler approach as an interim solution as I wait for my laser sintered stainless extension shaft.

One problem that I had was the electronic brake. The compressor wheel was slowing down too fast and the nut would come loose and the compressor wheel would lift off and touch the volute housing. I am tuning the brake settings and letting it coast a bit more and ordered a 10 mm x 12 point socket so that o can tighten the left hand thread nut in place without taking apart the assembly each time. I had initially applied the brake settings as a safety mechanism, but turns out that it might just make things more dangerous. For the final assembly I will probably use loctite, but right now it gets tore down and put back together several times a day.

Earlier in the week, I had only spun it up to about 0.1 PSI before things would get wonky. I didn’t even think the amp meter was working on the Electronic Speed Control data logger.

But with a more concentric and stable set up, I then spun it up to about 0.4 PSI, the 1 PSI today and was rejoicing. Then got bolder and wound it up to 1.5 PSI. Then I went for 2 PSI. I can’t remember where I finished but it was north of 2 PSI. I don’t know if I will get much beyond this without the new shaft which hopefully gets runout of less than 1-2 thousandths.

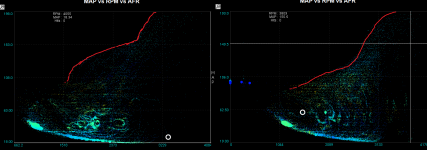

Below is the data log from the last pull of the day. At the 3rd peak is where we hit somewhere in the order of 2.2-2.4 PSI. I was so excited to be able to make boost! From here it is a matter of refinement, continuous improvementand optimization.

Here are some key observations I make when looking at this data.

- Lots of Data: I love having the data handy so that I can see what is going on and tune the system. That said the downside is that I am missing some data, like motor temperature and PSI as they are on different measuring devices. I was for instance happy to see that the ESC accurately tracked voltage and amps real time, so I could put my multimeter and amp probe away and focus my eyes elsewhere.

- Right Voltage: I decided to go with a higher voltage battery than the motor says it can handle. This is what I think WB said he was doing and confirmed by Castle. I built a 12 LiFePO4 cell x 3.25 volt battery = 39 volts nominal. This is where the purple line starts. But under load you can see it drops to 33 volts. Interestingly, the Castle 1721 says it can handle a maximum of 33.6 volts. I still need to get a proper charger as I am charger half the bank at a time.

- Digital RPM. I simply changed the setting in the app on my iPhone and configured the ESC for 4 pole motor. The digital readout on APP is then actual RPMs of the compressor wheel, since it is direct drive. The highest the RPM for was about 45,000. This motor is rated to 90,000 (which is where the rotor flies apart). I need to put a safeguard in to stay well below that number with a safety margin. That said, more RPMs = more boost!

- Amps: I thought that my ESC was not working right, but it turns out that it can’t really measure anything when idling along at just a few thousand RPMs. I was slowly getting more aggressive. On this last run at over 2 PSI, I hit over 71 amps (red line). Throttle (blue line) was at 39% and RPMs were an out 45,000. So, there is still some headroom and hope to get to the targeted 5-7 PSI boost.

- Heat. I have heard of lots of ESCs (electronic speed controller) blowing up and catching fire. So I spent extra money here and bought the biggest one I could afford (high end of the low end). It is a if chunk of meter with a lot of built in cooling and no surprise. It runs cool. It did not quite get up to body temperature. The motor. That was a different story. It got hot.